Wire Harness Production in Malaysia and Thailand: Challenges and Opportunities

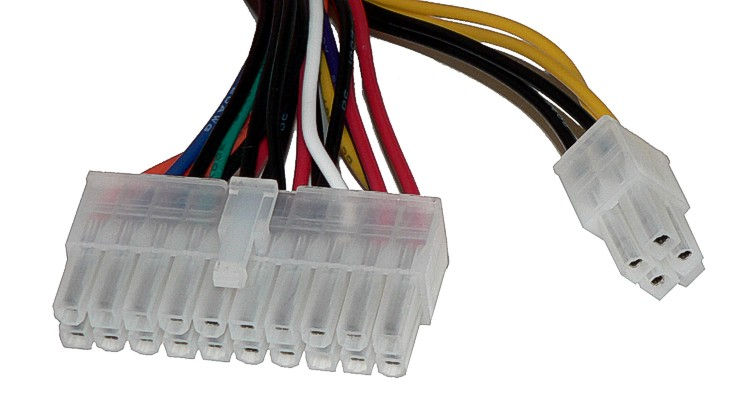

Wire harnesses are essential components for connecting electrical circuits in various industries, such as automotive, electronics, appliances, medical, and telecommunications. In this blog post, we will explore the wire harness production in two Southeast Asian countries: Malaysia and Thailand, and discuss some of the challenges and opportunities they face in this industry.

Malaysia is one of the leading wire harness manufacturers in the region, with a history of more than a decade in the field. The country has several wire harness companies that specialize in different sectors, such as automobile, electrical, refrigerated equipment, electronic sports equipment, and so on. Some of the advantages of wire harness production in Malaysia are:

- High quality and production-ready products at competitive prices

- Highly-trained technical experts and state-of-the-art manufacturing methods

- ISO 9001 and IATF 16949 certifications for quality management systems

- Licensed manufacturing warehouse (LMW) status for tax exemption and duty-free import of raw materials and machinery

- Strategic location near the Penang sea port for easy transportation and logistics

- International manufacturing partners from the United States, Japan, India, Denmark, and Netherlands

However, Malaysia also faces some challenges in wire harness production, such as:

- Low margins due to constant cost and price pressure from OEMs

- Stringent requirements for quality and delivery from OEMs

- Complex processes and continuous change due to design variations and customization

- Loss of tribal knowledge due to senior designers leaving or retiring

Wire Harness Production in Malaysia and Thailand

Malaysia is one of the leading wire harness manufacturers in the region, with a history of more than a decade in the field. The country has several wire harness companies that specialize in different sectors, such as automobile, electrical, refrigerated equipment, electronic sports equipment, and so on. Some of the advantages of wire harness production in Malaysia are:

- High quality and production-ready products at competitive prices

- Highly-trained technical experts and state-of-the-art manufacturing methods

- ISO 9001 and IATF 16949 certifications for quality management systems

- Licensed manufacturing warehouse (LMW) status for tax exemption and duty-free import of raw materials and machinery

- Strategic location near the Penang sea port for easy transportation and logistics

- International manufacturing partners from the United States, Japan, India, Denmark, and Netherlands

One of the examples of wire harness manufacturers in Malaysia is EH Success Solutions Sdn. Bhd, which was established in 2008 and has expanded its production capacity by 78% in 2013 and 58% in 2016. The company also invested in fully automatic machines for wire cutting, crimping, tinning, and speaker wire crimping operations. Another example is Chun Hau Electronic (M) Sdn. Bhd, which was founded in 1997 and has a subsidiary that offers a wide range of solutions for LAN cable connectors and optical cables. The company also provides contract manufacturing services for audio, computer, datacom, medical equipment, consumer electronics, automotive, home appliance, and test and measurement equipment industries.

Thailand is another major player in the wire harness production market, with a strong demand from the domestic and export markets. The country has a large automotive industry that consumes a lot of wire harnesses for cars and motorcycles. According to Statista, as of April 2023, approximately 1.4 million metric tons of wiring harness sets for cars and motorcycles were produced in Thailand, indicating a decrease from the previous month. In that same period, around 1.3 million metric tons of such items were sold in the country.

Thailand also has a number of wire harness companies that cater to various industries, such as EV trucks, agricultural machinery, heavy machine equipment, white goods products, mining industries, etc. Some of the benefits of wire harness production in Thailand are:

- Low labor cost and abundant workforce

- Government support and incentives for foreign investment

- Free trade agreements with ASEAN countries and other major markets

- High standard of quality control and testing

- Advanced technology and innovation

One of the examples of wire harness manufacturers in Thailand is MIS Thailand, which was established in 2017 and has been doing wire harnesses for EV trucks, automotive industries, agricultural machinery industries, heavy machine equipment industries, white goods products industries, mining industries, etc. The company uses fully automatic wire processing machines and final assembly by 100% electronically tested final products.

In conclusion, wire harness production is a thriving industry in both Malaysia and Thailand, with different strengths and opportunities. Both countries offer high-quality products and services at competitive prices to meet the diverse needs of various industries. Wire harness production is also a key factor for economic development and technological advancement in the region.

Insightful content! AEO (Answer Engine Optimization) is key to improving search visibility in featured snippets and voice search results. Optimizing content with structured data and AI-driven strategies enhances user experience and boosts organic rankings. As search engines evolve, implementing AEO services is essential for staying ahead in digital marketing.

Need help crafting the perfect CV? Our CV Writing Service in Ireland provides professional support for job seekers, including one-to-one assistance from our Graduate CV writers. We specialise in crafting professional resumes and provide cover letter writing help in Dublin to make your application stand out.